Now I am running into all kinds of questions as I try to set this up. I just finished ordering my G540įor the 3D printer I am going to build I only need two actuators so the GRBLshield will work great. I will post screenshots this week which make the axis setup straightforward. You select the Gecko 540 from the controller list, and the next few steps are configuring your axis (steps/inch). Then you select "stepconfig" from the CNC control menu, and create a new machine.

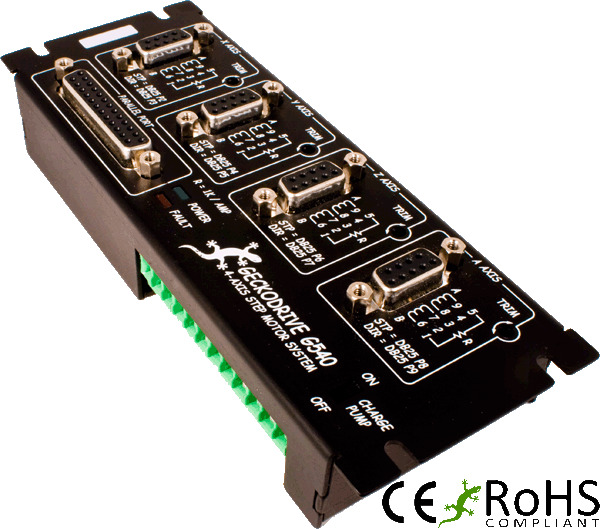

GECKO G540 CONTROLLER INSTALL

Basically you download the install CD from, and go through the setup like you would to install windows. It is very easy and straight forward, but I say that having installed it twice and being an Ubuntu guy to begin with. This is a nice setup and good price for an all-in-one system, sans motors and wiring.

On your 50V, 1A output, I'm pretty sure that only applies if you are providing 50V to the Gecko540 and your power supply can provide sufficient current. One key is you need to wire resistors into the stepper motor wire leads to set the current. 40-review/Īlso plenty of documentation, schematics etc. Here is a reasonable review and setup steps. I can't be of too much help on the Gecko 540 front, other than to say my friends that own them on their Joes 4x4 CNC's and similar love them and have no problems. I have been reading through the forums over at, but there is a ton of information for a million different configurations that I do not fully understan. It looks like there are two outputs rated at 50V 1A that I would want to use as a spindle enable/disable running a 24VDC latching relay, what would be the best configuration?Īlso I do not know anything about linuxcnc, or how that would be used in this application so any other information would be great.

GECKO G540 CONTROLLER PC

I would like to see a simple one line diagram from PC to stepper including additional options and system settings (Limit switches, spindle run relays, voltage and current settings, things like that). I want to build a 3d printer, so I am upgrading my CNC and utilizing all the parts off of it for the printer. I do have some questions though, and I was wondering if there were any other members on here running one that would have a minute to describe their setup to me and any other considerations that I should I think about prior to making the switch. It looks to be the perfect size and have all the different options that I would need to run my system. I am thinking of getting a G540 and building a better controller for my CNC.

0 kommentar(er)

0 kommentar(er)